The system

Automation designed for your cleanroom

POUL doesn’t just provide you with a robot. We deliver a complete, tailored system for automated material transport: hardware, software, project management, documentation, certificates — everything you need to operate without a headache.

01

Hardware

Hygienic mobile robots at the heart of operation

Cleanroom compliant charging stations

Hygienic pallet magazines

Cleaning tools

02

Software

GAMP5-compliant logistics system

ERP / WMS / MES integration

Vendor-agnostic fleet management

Safety system

Communication with external equipment

03

Validation & Documentation

Certificates

Project management

Full documentation package

Factory and site acceptance tests

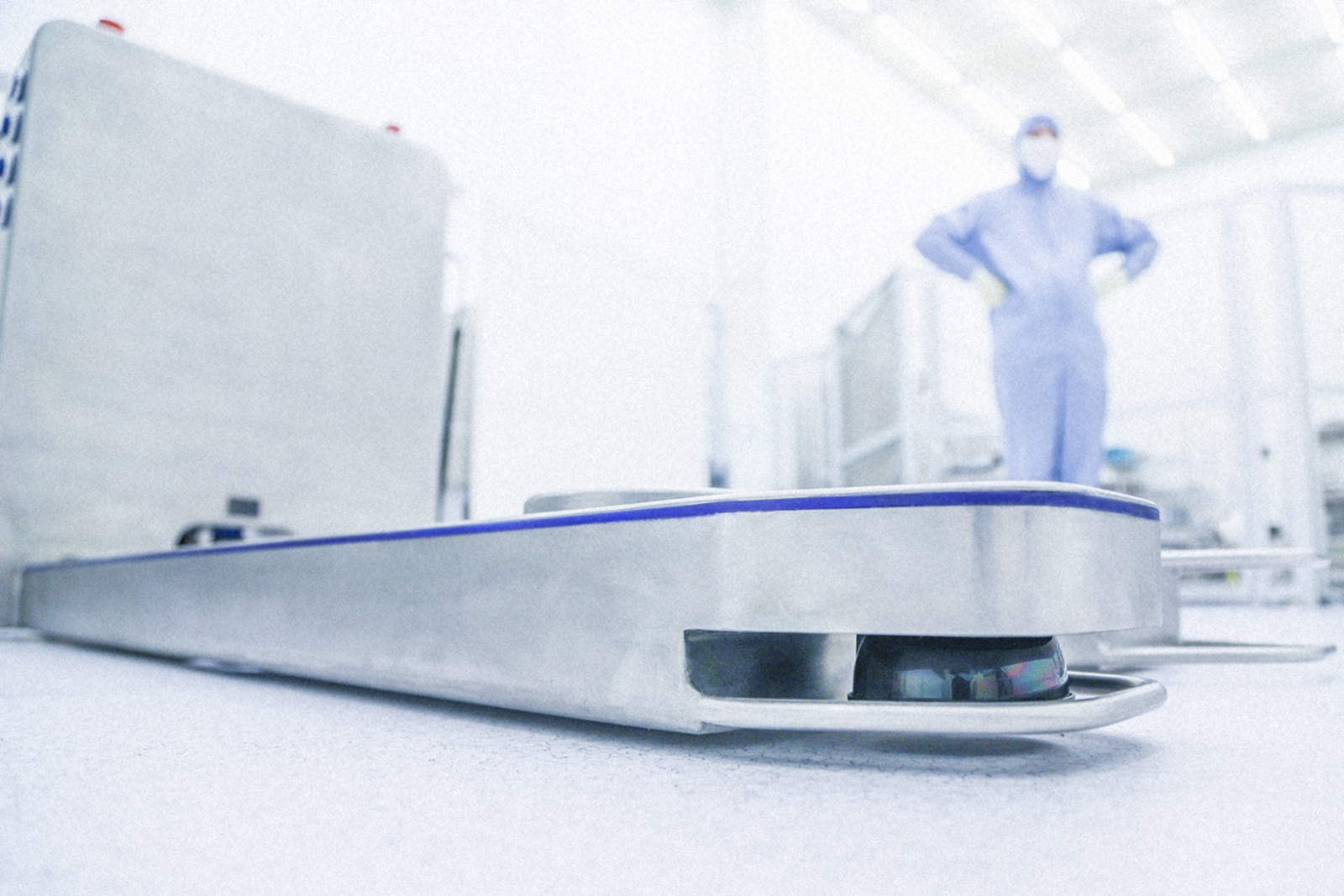

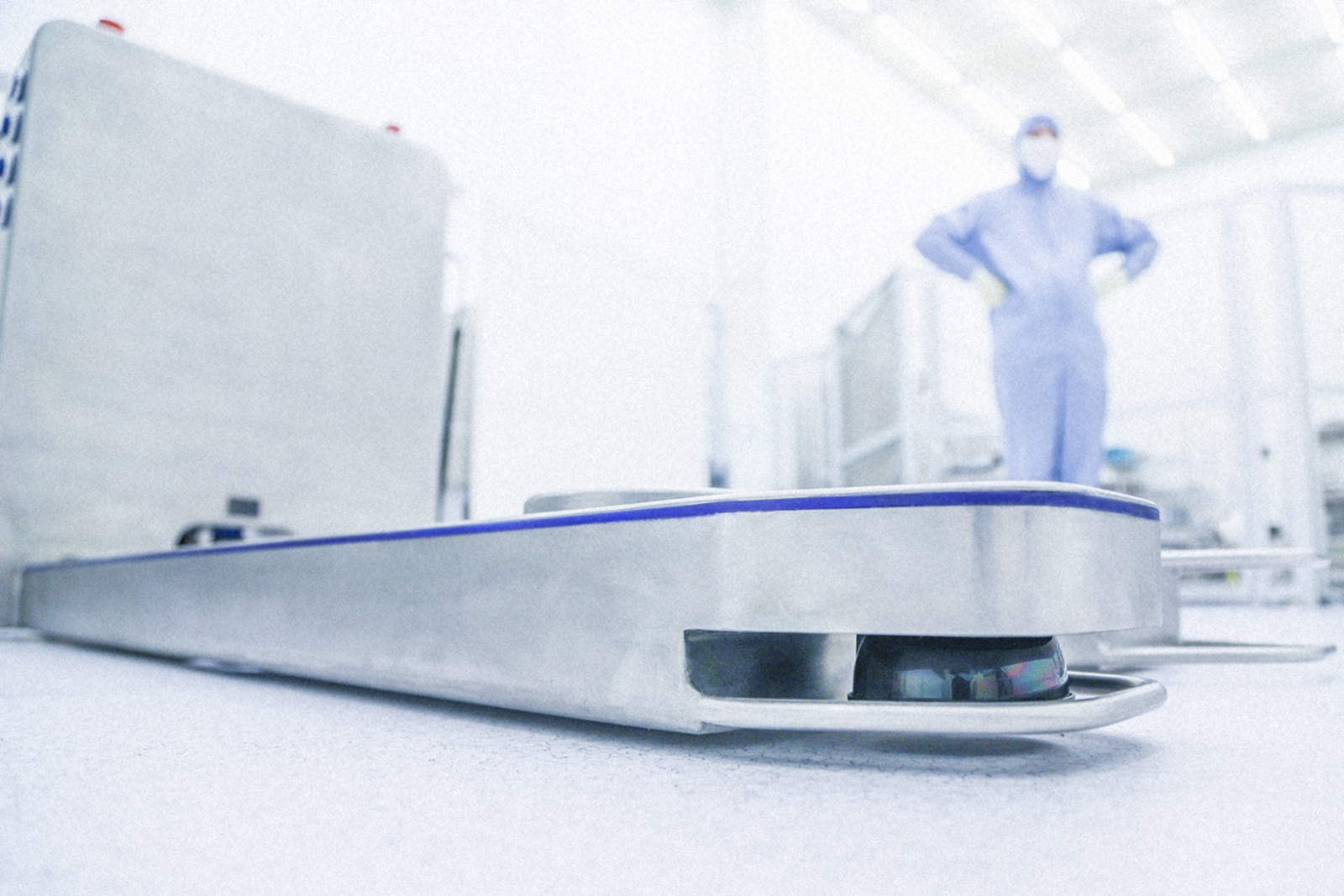

The robot

The fork. Simple. Clean.

Soon to be iconic.

Features

1000 kg standard payload

Customizable fork design for a variety of payloads.

Hygienic design

Designed according to EHEDG, 3A and ISO guidelines.

Low particle emission

Engineered to minimize particle generation.

Use-case inspiration

API

Transport of bioreactors and fermentation/cultivation tanks.

Formulation

Transport of APIs, excipients and mixing tanks.

Containment & ATEX

Safe transport in high-containment and solvent storage areas.

Raw material handling

Infeed of raw materials to fermentation process.

Filling line operations

Supply of tubs, closures, plungers and removal of waste.

Between grades

Automated transfer of goods between cleanroom grades.

Industry challenges

Accept manual operation risks or build an automated system.

Contamination risks

Protecting the product is crucial for patient safety, quality, and compliance. Still, most production environments rely heavily on manual operation increasing risk of contamination.

Safety & performance risks

We ask operators to perform with machine-like precision in critical environments. It's an unfair expectation and an unnecessary risk for operator safety.

Higher demand, stricter regulations

Novel medicines drive a global increase in production capacity. Meanwhile regulators demand higher standards that manual and paper-based processes can hardly meet.

Legacy processes

Other industries have long been utilizing robotics to drive down cost. Conservative choices and lack of appropriate technology have slowed down the adoption of robots in pharma.

We guide > We build > We stay

Projects

From first meeting to operations

01

Intro & scoping

02

Project definition

03

Integrator onboarding

04

Tender phase

05

Project execution

06

FAT validation

07

SAT validation

08

Handover & training

09

Ongoing support

Benefits

Autonomous Mobile Robots pay off — in more than numbers.

Safer work environment

Increased capacity and better scalability

Improved product protection

Real-time data

Predictable production

Optimized space

Leaner processes

Less environmental monitoring

More environmentally sustainable operations

Fully digitized workflow

About

POUL is

The trustworthy operator who knows every bolt by name.

The aseptic specialist who preaches patient safety.

The considerate designer who demands user-friendliness.

The reliable engineer who obsesses over every little detail.

The helpful QA who guides you through the maze of pharma requirements.

POUL was born in 2023 with the aim of bringing robots to pharmaceutical cleanrooms and other clean production environments. Since then, we’ve been on a wild journey, have met fantastic people, and carefully listened to many opinions.

Our first product, the fork, serves as a baseline for upcoming developments that we’re already working on. Stay tuned and connect with us on LinkedIn. We’d love to hear from you.

Founders

With over 10 years of expertise in cleanroom operations and pharma manufacturing, Julie steers GMP compliance, quality assurance, and project delivery at POUL. Janik’s background in optimizing cleanroom equipment for aseptic production drives POUL’s design, engineering & product development. Together, we build customer relations, partnerships, and commercial growth.

Be the first to know

Friends, partners, & customers

POUL stands for partnerships

We exclusively collaborate with the best in the industry. They are trusted partners to ensure safety, quality, and efficiency.

“Working with POUL was a markedly different experience. From the very beginning, I was met with deep industry insight, a strong grasp of compliance expectations, and a clear appreciation for the importance of thorough documentation of their delivery throughout the design phases.”

Anders Bo Andersen

Senior Specialist,

Process Systems Intelligence

NNE

We build for cleanrooms

Be the first to know

We build for cleanrooms

The system

Automation designed for your cleanroom

POUL doesn’t just provide you with a robot. We deliver a complete, tailored system for automated material transport: hardware, software, project management, documentation, certificates — everything you need to operate without a headache.

01

Hardware

Hygienic mobile robots at the heart of operation

Cleanroom compliant charging stations

Hygienic pallet magazines

Cleaning tools

02

Software

GAMP5-compliant logistics system

ERP / WMS / MES integration

Vendor-agnostic fleet management

Safety system

Communication with external equipment

03

Validation & Documentation

Certificates

Project management

Full documentation package

Factory and site acceptance tests

The robot

The fork. Simple. Clean.

Soon to be iconic.

Features

1000 kg standard payload

Customizable fork design for a variety of payloads.

Hygienic design

Designed according to EHEDG, 3A and ISO guidelines.

Low particle emission

Engineered to minimize particle generation.

Use-case inspiration

API

Transport of bioreactors and fermentation / cultivation tanks.

Formulation

Transport of APIs, excipients, and mixing tanks.

Raw material handling

Infeed of raw materials to fermentation process.

Containment & ATEX

Safe transport in high-containment and solvent storage areas.

Filling line operations

Supply of tubs, closures, plungers and removal of waste.

Between grades

Automated transfer of goods between cleanroom grades.

Industry challenges

Accept manual operation risks or build an automated system.

Contamination risks

Protecting the product is crucial for patient safety, quality, and compliance. Still, most production environments rely heavily on manual operation increasing risk of contamination.

Safety & performance risks

We ask operators to perform with machine-like precision in critical environments. It's an unfair expectation and an unnecessary risk for operator safety.

Higher demand, stricter regulations

Novel medicines drive a global increase in production capacity. Meanwhile regulators demand higher standards that manual and paper-based processes can hardly meet.

Legacy processes

Other industries have long been utilizing robotics to drive down cost. Conservative choices and lack of appropriate technology have slowed down the adoption of robots in pharma.

We guide > We build > We stay

Projects

From first meeting to operations

01

Intro & scoping

02

Project definition

03

Integrator onboarding

04

Tender phase

05

Project execution

06

FAT validation

07

SAT validation

08

Handover & training

09

Ongoing support

Benefits

Autonomous Mobile Robots pay off — in more than numbers

Safer work environment

Increased capacity and better scalability

Improved product protection

Real-time data

Predictable production

Optimized space

Leaner processes

Less environmental monitoring

More environmentally sustainable operations

Fully digitized workflow

Be the first to know

About

POUL is...

The trustworthy operator who knows every bolt by name.

The aseptic specialist who preaches patient safety.

The considerate designer who demands user-friendliness.

The reliable engineer who obsesses over every little detail.

The helpful QA who guides you through the maze of pharma requirements.

The helpful QA who guides you through the maze of pharma requirements.

POUL was born in 2023 with the aim of bringing robots to pharmaceutical cleanrooms and other clean production environments. Since then, we’ve been on a wild journey, have met fantastic people, and carefully listened to many opinions. Our first product, the fork, serves as a baseline for upcoming developments that we’re already working on. Stay tuned and connect with us on LinkedIn. We’d love to hear from you.

Founders

With over 10 years of expertise in cleanroom operations and pharma manufacturing, Julie steers GMP compliance, quality assurance, and project delivery at POUL. Janik’s background in optimizing cleanroom equipment for aseptic production drives POUL’s design, engineering & product development. Together, we build customer relations, partnerships, and commercial growth.

Friends, partners, & customers

POUL stands for partnerships

We exclusively collaborate with the best in the industry. They are trusted partners to ensure safety, quality, and efficiency.

“Working with POUL was a markedly different experience. From the very beginning, I was met with deep industry insight, a strong grasp of compliance expectations, and a clear appreciation for the importance of thorough documentation of their delivery throughout the design phases.”

Anders Bo Andersen Senior Specialist, Process Systems Intelligence

NNE